Single passage Rotary Union Knowledge

Details knowledge of signle passage rotary union

Single Passage Rotary Joint

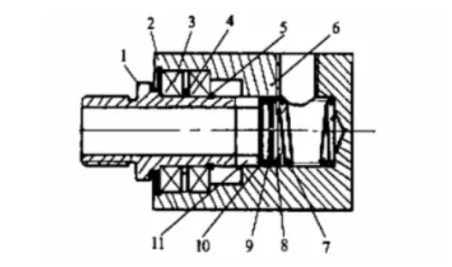

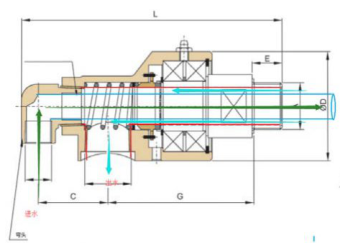

The connection method for a single-circuit swivel joint can be selected according to the working conditions. The inlet for transmitting media can be freely selected from the side or rear depending on the working situation. The sealing surface and sealing ring are made of special materials, resistant to wear, long-lasting, corrosion-resistant, and leak-proof. There are two precision bearings inside the swivel joint, ensuring smooth and durable operation, sturdy and flexible, with a small friction coefficient, allowing for high-speed operation. The condition of internal sealing parts wearing can be visually inspected from the exterior of the product, which can prevent mechanical shutdown or damage, thereby achieving preventive effects and reducing losses. The replacement and repair of worn sealing parts are simple, without the need to purchase new products, saving costs. The structure of a single-circuit swivel joint is shown in Figure 1, where pipe joint 1 connects the rotating part to the rotating chamber, and joint body 6 connects the stationary part to the stationary chamber. The sealing portion consists of 7, 8, 9, 10, and 11. This structure has only one fluid passage.

Figue 1 The structure of single passage rotary joint

- 1.Pipe joint

- 2.Inner card

- 3.Bearing

- 4.Sleeve

- 5.Outer card

- 6.Joint body

- 7.Spring

- 8.Washer

- 9.Seal ring

- 10.Washer

- 11.Rubber sleeve

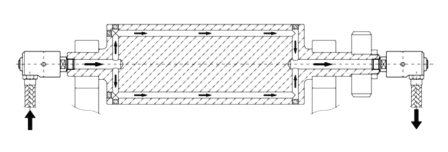

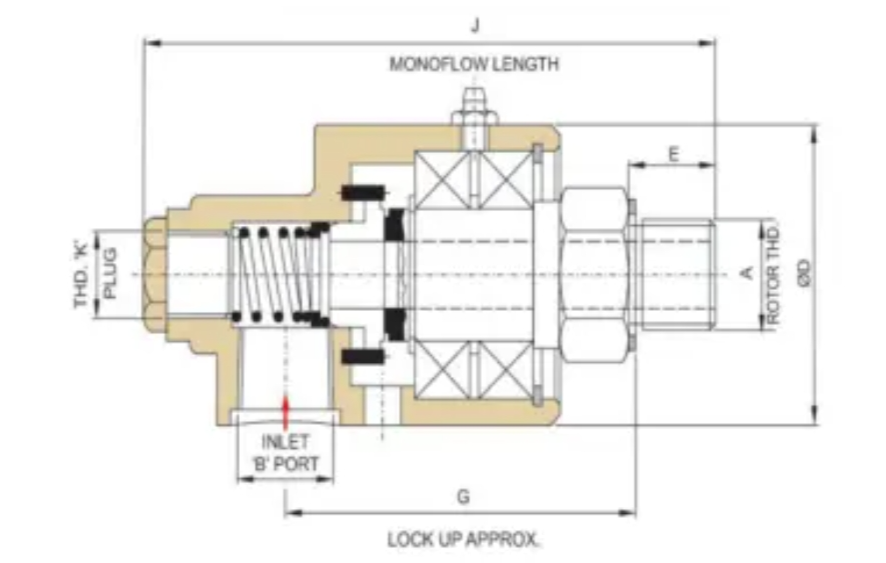

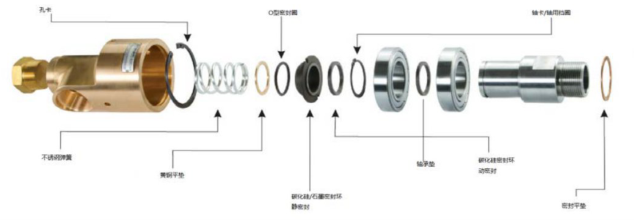

Single-circuit swivel joints can be further divided into single passage and double passage structures, as shown in the diagram below. This is a schematic representation of monoflow swivel joint, along with its internal structure.

Monoflow type

Below is Dual-flow type

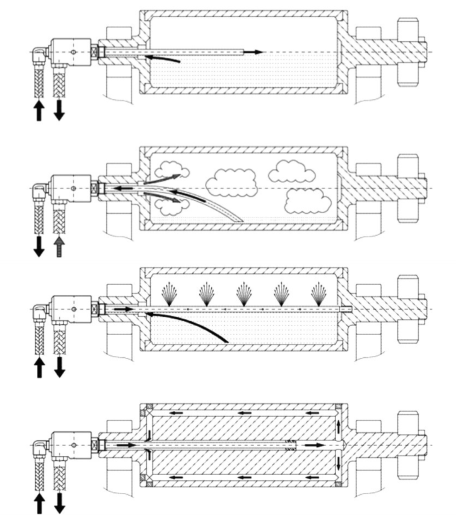

The sealing structure of swivel joints mainly includes three types: flat seal (mechanical seal), spherical seal (concave-convex close-fitting seal), and line seal (O-ring seal). The following diagram illustrates the most commonly used flat seal structure.

Installation Guidelines for Swivel Joints:

- 1.During transportation and storage, swivel joints should be handled with care to avoid impacts and drops, which could damage the interfaces and internal components.

- 2.Install the swivel joint as concentrically as possible to ensure smooth operation.

- 3.When installing swivel joints with threaded connections, pay attention to whether the thread direction of the inner and outer pipes corresponds to the rotation direction of the drum, and ensure that the thread rotation directions of the inner and outer pipes are consistent.

- 4.The connection between the swivel joint and the pipeline must be made using flexible hoses (preferably using flexible metal hoses), rigid connections are strictly prohibited.

- 5.Whenever possible, connect the inlet and outlet of the swivel joint directly to flexible hoses to reduce the additional weight on the joint and extend its service life.

- 6.During assembly of the inner pipe, pay attention to the dimensional fit and provide auxiliary support for the weight. For internal swivel joints, it is recommended to use H8/e7 tolerance fit for the mating of the inner pipe and joint.

- 7.Proper support and anti-rotation measures should be taken for the swivel joint. The diameter of the supporting rod should generally be 2mm smaller than the anti-rotation hole to avoid affecting the free adjustment and compensation of the swivel joint.